General technical description of lifts

Technical description of passenger lifts, freight lifts, and parking systems:

The Pavol Tuchyňa, Tuchyňa – Výťahy Company supplies passenger lifts of all categories. As the name indicates, passenger lifts are used for vertical transport of persons.

Passenger lifts of the Tuchyňa - Výťahy Company represent the main domain of the company and this category is currently in the process of the most intensive development.

Main groups of passenger lifts and their classification are described in the paragraphs below.

- Lift’s carrying capacity

- Travel speed

- Shaft type

- Drive location

- Drive type

- 250 kg – 6,000 kg (passenger lifts, freight lifts, and parking systems)

Carrying capacity of lifts depends on cabin dimensions. Cabin dimensions are adjusted to shaft dimensions and are designed according to the required capacity requirements. Lift carrying capacity generally ranges between 250 kg – 6,000 kg.

TRAVEL SPEED – 0.63 m/s– 4 m/s

- Above 4 m/s (special solutions)

Travel speed of lifts is determined by the EN 81-1,2 standard, depending on number of stations, required transport capacity and a customer’s demand. Standard travel speed ranges between 1.0 m/s and 1.6 m/s for lifts with up to 20 stations. In case of high-speed lifts with the travel speed above 4m/s the Tuchyňa - Výťahy company in cooperation with its partners is able to offer special solutions as well.

In 2011, our company launched a new series of the ACT control for traction lifts with possible extension to 32 stations and control of eight lifts in a group control. In case of hydraulic system, the ACH type is used for 16 stations.

All delivered control systems contain below mentioned functions and by adjusting the parameters they can be modified at any time during the operation.

Standard parameters:

- simplex, duplex, triplex control, up to 8 lifts in a group,

- parallel communication, serial communication from the cabin operating panel (COL), serial communication from COL and landing operating panels (LOPs),

- control circuit with 3 phases and temperatures (thermistor),

- detailed list of error reports (date, time, error) with the memory of up to 250 errors,

- short calls and sending of detailed GSM messages in case of failure,

- exact time and date,

- connection to control system using a PC via the Internet, local network and USB, lift monitoring,

- CAN – bus communication in the shaft and in the group,

- pursuant to EN81-1 standard, CE certified control system,

- pursuant to EN81-72, fire protection standard for lifts,

- detectors, shaft encoder, and regulation encoder with output for data on individual storeys,

- special software for protection against undesired access to the lift control system

Shaft type:

- Ferro-concrete

- Brick

- Metal – lined with a solid wall.

- Metal with glass walls – panoramic shafts

Lift portfolio includes solutions for all shaft types, whereas all the components are adjusted to these requirements, whether regarding technical, static, or aesthetic aspects.

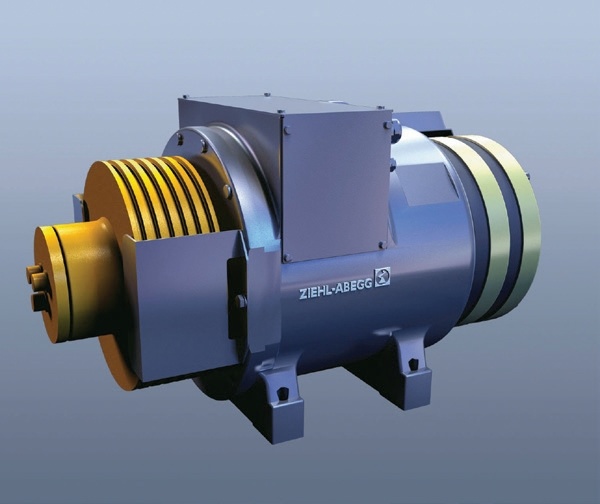

Traction machines:

Hydraulic drives are currently used mainly for lifts with lower travel rise, lower required speed, and high carrying capacity. An advantage of the hydraulic system is a very low noise level, possible use with lifts with a high carrying capacity; moreover, this system provides high reliability.

For lifts using traction machines, the Pavol Tuchyňa, Tuchyňa – Výťahy company uses exclusively the most advanced technology, particularly the synchronous gearless machines that permanently use magnets. Gearless synchronous lift machines are characteristic with plenty of advantages, compared to conventional geared machines.

Energetic efficiency and saving - energy saving compared to conventional drives ranging between 45 and 55 %

Minimum maintenance - no oil or fat media

Long life - minimum number of rotating parts and no gears

Environment and ecology - low energy consumption, exclusion of lubricating oils

Fast economic return - energy saving rate reduces the recoupment period

Silent operation - low noise level of machines with possible placement into lift shafts for the so-called machine room-less lifts

Comfortable travel and emergency drive - smooth start, landing, and stopping, smooth lift travel

Manual drive - machine room versions enable safe cabin sliding using the manual brake release and removable manual wheel

| Type/opening system | Machine control | Number of panels | Frame type | |

| Cabin | at./ce,te ; at.bus/fold. | vvvf | 2,3,4,6, | portal |

| Landing | m ; at./ce,te | m.*/ vvvf | 1*, 2,3,4,6 | f, fl |

|

at - automatic at.bus - bus-type automatic m* - manual fl - frameless door |

vvvf - frequency regulation ce - central te - telescopic * - (applicable to manual door only) |

f - frame door 1* - single-wing fold* - folding |

| Fire resistance of landing door | Surface finish | |||

| - ew 30 - (standard) | - ew 60, 90 | - Electrostatic spray application ral (standard) | - Clear safety glass Konex | |

| - ei 30, 60, 90 | - Stainless steel | - Decoglass, Aldeco, Hpl | ||

registered office : Letná 27, 040 01 Košice, Slovakia

owner : Pavol Tuchyňa

phone number : 00421-55-632 33 98

fax : 00421-55-632 33 83